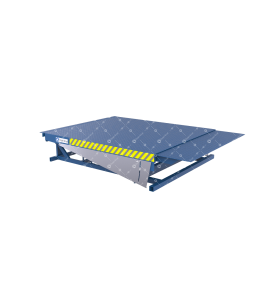

Galvanized lift tables are ideal for outdoors and other demanding environments with moisture.

Lift Tables

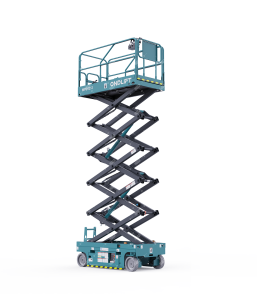

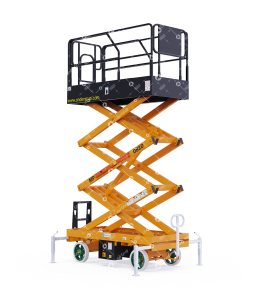

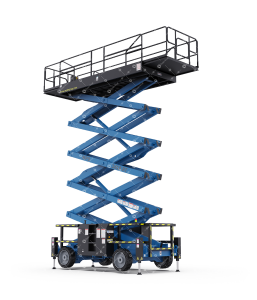

Galvanized Lift Table

Galvanized lift tables are ideal for outdoors and other demanding environments with moisture.

STANDART MODELS

| Type | Art No () | Capacity (kg) | E X F - Platform Dimensions (M) | H - Stroke (mm) | C - Closed Height (M) | Lifting Time (sn) | Engine (kW) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

|

Filter

|

||||||||

| ESP.G.1/05-06 | 47.05.001 | 500 | 950 x 600 | 600 | 180 | 8 | 0,75 | 140 |

| ESP.G.1/05-09-1 | 47.05.002 | 500 | 1350 x 800 | 820 | 180 | 18 | 0,75 | 200 |

| ESP.G.1/05-09-2 | 47.05.003 | 500 | 1350 x 1000 | 820 | 180 | 18 | 0,75 | 220 |

| ESP.G.1/05-09-3 | 47.05.004 | 500 | 1500 x 1000 | 820 | 180 | 18 | 0,75 | 230 |

| ESP.G.1/05-12 | 47.05.005 | 500 | 1800 x 1000 | 1200 | 230 | 32 | 0,75 | 250 |

| ESP.G.1/10-06 | 47.10.100 | 1000 | 950 x 600 | 600 | 180 | 12 | 0,75 | 180 |

| ESP.G.1/10-09-1 | 47.10.101 | 1000 | 1350 x 800 | 820 | 180 | 20 | 0,75 | 210 |

| ESP.G.1/10-09-2 | 47.10.102 | 1000 | 1350 x 1000 | 820 | 180 | 20 | 0,75 | 230 |

| ESP.G.1/10-09-3 | 47.10.103 | 1000 | 1500 x 1000 | 820 | 180 | 20 | 0,75 | 240 |

| ESP.G.1/10-12 | 47.10.104 | 1000 | 1800 x 1000 | 1200 | 260 | 34 | 0,75 | 380 |

| ESP.G.1/10-13 | 47.10.105 | 1000 | 2000 x 1200 | 1300 | 260 | 32 | 1,1 | 400 |

| ESP.G.1/10-16 | 47.10.106 | 1000 | 2250 x 1500 | 1600 | 300 | 35 | 1,1 | 550 |

| ESP.G.1/15-09-1 | 47.15.200 | 1500 | 1350 x 800 | 820 | 180 | 28 | 0,75 | 280 |

| ESP.G.1/15-09-2 | 47.15.201 | 1500 | 1350 x 1000 | 820 | 180 | 28 | 0,75 | 290 |

| ESP.G.1/15-09-3 | 47.15.202 | 1500 | 1500 x 1000 | 820 | 180 | 28 | 0,75 | 320 |

| ESP.G.1/15-12 | 47.15.203 | 1500 | 1800 x 1000 | 1200 | 260 | 32 | 1,1 | 380 |

| ESP.G.1/15-13 | 47.15.204 | 1500 | 2000 x 1200 | 1300 | 260 | 35 | 1,5 | 420 |

| ESP.G.1./15-16 | 47.15.205 | 1500 | 2250 x 1500 | 1600 | 300 | 36 | 1,5 | 580 |

| ESP.G.1/20-09-1 | 47.20.300 | 2000 | 1350 x 800 | 820 | 230 | 28 | 0,75 | 290 |

| ESP.G.1/20-09-2 | 47.20.301 | 2000 | 1350 x 1000 | 820 | 230 | 28 | 0,75 | 300 |

| ESP.G.1/20-09-3 | 47.20.302 | 2000 | 1500 x 1000 | 820 | 230 | 28 | 0,75 | 330 |

| ESP.G.1/20-12 | 47.20.303 | 2000 | 1800 x 1000 | 1200 | 260 | 32 | 1,1 | 400 |

| ESP.G.1/20-13 | 47.20.304 | 2000 | 2000 x 1200 | 1300 | 260 | 35 | 1,5 | 440 |

| ESP.G.1/20-14 | 47.20.305 | 2000 | 2250 x 1500 | 1600 | 300 | 36 | 1,5 | 700 |

| ESP.G.1/20-15 | 47.20.306 | 2000 | 2500 x 1500 | 1600 | 320 | 34 | 2,2 | 740 |

| ESP.G.1/20-16 | 47.20.307 | 2000 | 3000 x 2000 | 2000 | 350 | 34 | 2,2 | 1100 |

| ESP.G.1/30-09-1 | 47.30.400 | 3000 | 1350 x 800 | 820 | 300 | 20 | 2,2 | 380 |

| ESP.G.1/30-09-2 | 47.30.401 | 3000 | 1350 x 1000 | 820 | 300 | 20 | 2,2 | 400 |

| ESP.G.1/30-09-3 | 47.30.402 | 3000 | 1500 x 1000 | 820 | 300 | 20 | 2,2 | 420 |

| ESP.G.1/30-12 | 47.30.403 | 3000 | 1800 x 1000 | 1200 | 300 | 26 | 2,2 | 490 |

| ESP.G.1/30-13 | 47.30.404 | 3000 | 2000 x 1200 | 1300 | 320 | 32 | 2,2 | 560 |

| ESP.G.1/30-16-1 | 47.30.405 | 3000 | 2250 x 1500 | 1600 | 320 | 32 | 2,2 | 700 |

| ESP.G.1/30-16-2 | 47.30.406 | 3000 | 2500 x 1500 | 1600 | 350 | 45 | 2,2 | 780 |

| ESP.G.1/30-20 | 47.30.407 | 3000 | 3000 x 2000 | 2000 | 350 | 50 | 2,2 | 1200 |

| ESP.G.1/40-09-1 | 47.40.500 | 4000 | 1350 x 1000 | 820 | 300 | 22 | 2,2 | 500 |

| ESP.G.1/40-09-2 | 47.40.501 | 4000 | 1500 x 1000 | 820 | 300 | 22 | 2,2 | 550 |

| ESP.G.1/40-12 | 47.40.502 | 4000 | 1800 x 1000 | 1200 | 320 | 27 | 3 | 600 |

| ESP.G.1/40-13 | 47.40.503 | 4000 | 2000 x 1200 | 1300 | 350 | 30 | 3 | 800 |

| ESP.G.1/40-16-1 | 47.40.504 | 4000 | 2250 x 1500 | 1600 | 350 | 30 | 3 | 1100 |

| ESP.G.1/40-16-2 | 47.40.505 | 4000 | 2500 x 1500 | 1600 | 400 | 40 | 4 | 1200 |

| ESP.G.1/40-20 | 47.40.506 | 4000 | 3000 x 2000 | 2000 | 400 | 46 | 4 | 1600 |

| ESP.G.1/50-09 | 47.50.600 | 5000 | 1500 x 1000 | 820 | 400 | 26 | 2,2 | 650 |

| ESP.G.1/50-10 | 47.60.601 | 5000 | 1800 x 1000 | 1000 | 400 | 30 | 2,2 | 800 |

| ESP.G.1/50-11 | 47.60.602 | 5000 | 2000 x 1200 | 1100 | 400 | 34 | 3 | 1000 |

| ESP.G.1/50-13 | 47.60.603 | 5000 | 2250 x 1500 | 1300 | 400 | 34 | 3 | 1300 |

| ESP.G.1/50-16 | 47.60.604 | 5000 | 2500 x 1500 | 1600 | 400 | 30 | 3 | 1500 |

| ESP.G.1/50-20 | 47.60.605 | 5000 | 3000 x 2000 | 2000 | 400 | 56 | 4 | 1900 |

| ESP.G.1/60-10 | 47.60.700 | 6000 | 1800 x 1000 | 1000 | 400 | 34 | 3 | 1100 |

| ESP.G.1/60-11 | 47.60.701 | 6000 | 2000 x 1200 | 1100 | 400 | 38 | 3 | 1300 |

| ESP.G.1/60-13 | 47.60.702 | 6000 | 2250 x 1500 | 1300 | 400 | 40 | 4 | 1600 |

| ESP.G.1/60-16 | 47.60.703 | 6000 | 2500 x 1500 | 1600 | 400 | 48 | 4 | 1800 |

| ESP.G.1/60-18 | 47.60.704 | 6000 | 3000 x 2000 | 1800 | 400 | 60 | 4 | 2200 |

| ESP.G.1/80-11 | 47.80.800 | 8000 | 2000 x 1200 | 1100 | 500 | 38 | 4 | 1500 |

| ESP.G.1/80-13 | 47.80.801 | 8000 | 2250 x 1500 | 1300 | 500 | 40 | 4 | 1800 |

| ESP.G.1/80-16 | 47.80.802 | 8000 | 2500 x 1500 | 1600 | 600 | 48 | 5,5 | 2000 |

| ESP.G.1/80-18 | 47.80.803 | 8000 | 3000 x 2000 | 1800 | 600 | 60 | 5,5 | 2600 |

| ESP.G.1/100-15 | 47.10.900 | 10000 | 2500 x 1500 | 1500 | 600 | 48 | 5,5 | 2250 |

| ESP.G.1/100-18 | 47.10.901 | 10000 | 3000 x 2000 | 1800 | 600 | 60 | 7,5 | 2800 |

Do you need custom designed lifting solutions?

Contact a Lift Expert Today.